Search

Screen filter is a precision device that directly intercepts impurities in the water with a filter screen. It removes suspended solids and particles, reduces turbidity, purifies water quality, minimizes system fouling, bacteria, algae, rust, and protects other equipment in the system for normal operation.

In agricultural irrigation, screen filters are often used in conjunction with primary filters as secondary filter, which can effectively prevent blockages in devices like irrigators.

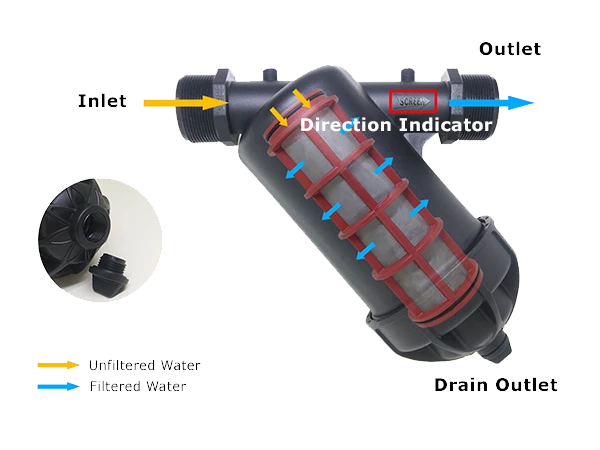

The screen filter mainly consists of a tank and a filter screen. Untreated water flows into the tank through the inlet, where impurities larger than the mesh aperture are intercepted on the outer surface of the filter screen. The water filtered through the screen flows towards the outlet, thus achieving the purpose of purifying water quality and protecting subsequent equipment from malfunction due to blockage by impurities.

The filter element is made of stainless steel wire mesh, and its filtering capacity is determined by the mesh count. The higher the mesh count, the better its filtering capacity.

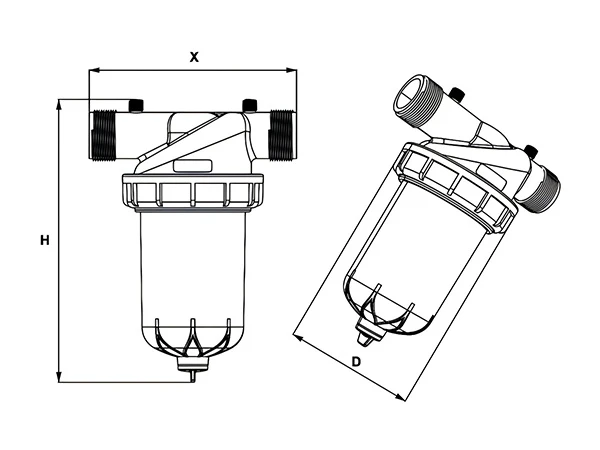

Y-type screen filter

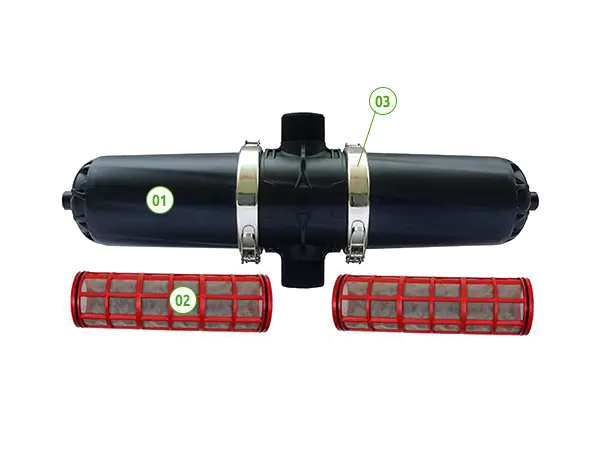

T-type screen filter

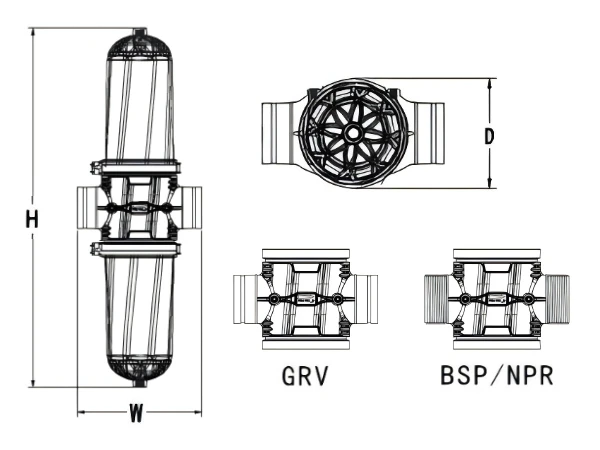

H-type screen filter

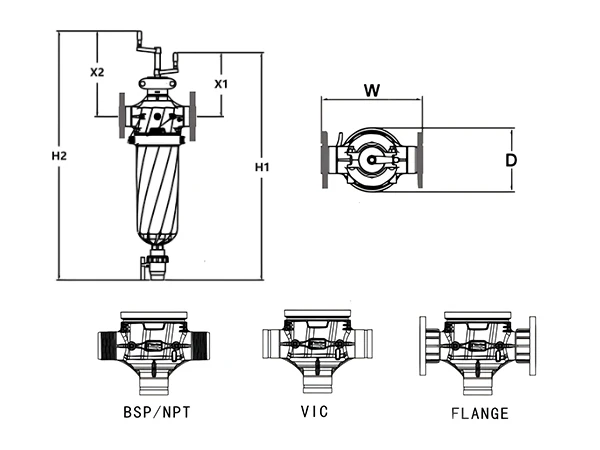

Hand-cranked screen filter

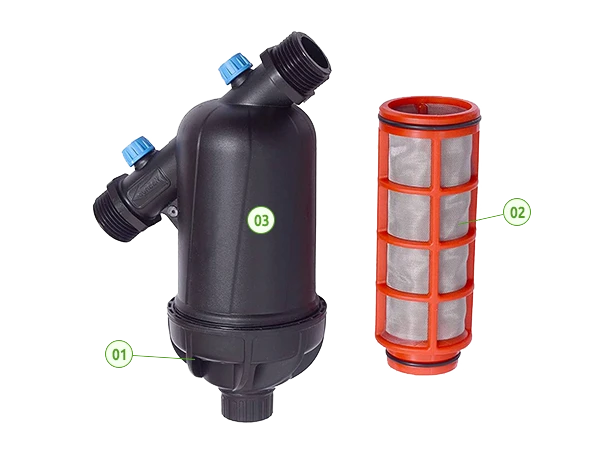

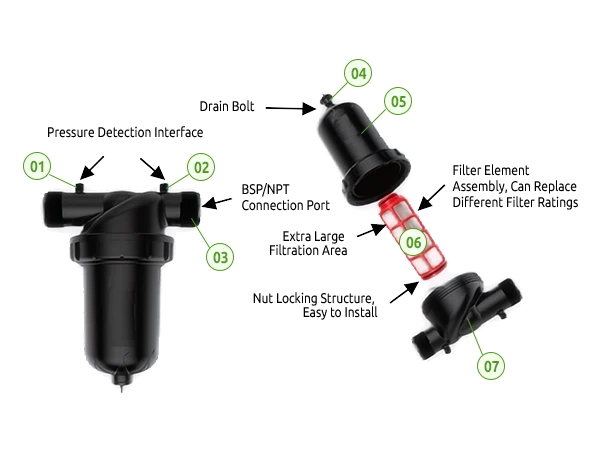

The Y-type screen filter mainly consists of a filter element, housing, and top cover. The housing is made of high-pressure-resistant plastic, and the filter element is made of stainless steel mesh. Its inlet and outlet are usually located on the same side, forming a 'Y' shape. This design is typically used for quick sewage discharge.

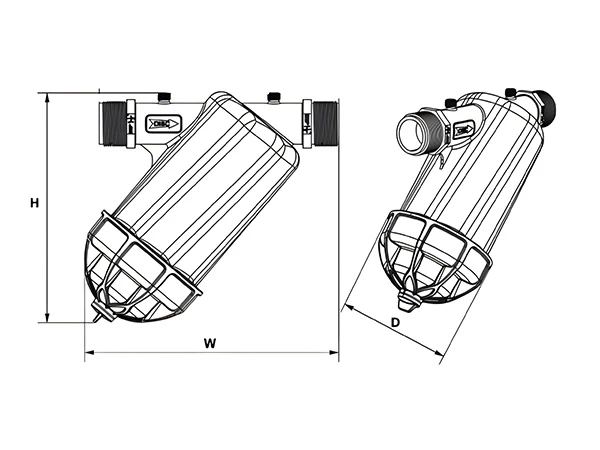

| Model | H (mm) |

W (mm) |

D (mm) |

|---|---|---|---|

| YS-1 | 173 | 176 | 93 |

| YS-2 | 173 | 192 | 83 |

| YS-3 | 173 | 176 | 93 |

| YS-4 | 173 | 192 | 83 |

| YS-5 | 230 | 250 | 120 |

| YS-6 | 230 | 250 | 120 |

| YS-7 | 260 | 290 | 140 |

| YS-8 | 330 | 360 | 168 |

| YS-9 | 330 | 360 | 168 |

| Model | Connection Pipe Diameter BSP/NPT |

Filter Rating (Mesh) |

Maximum Flow Rate (m3/h) |

Maximum Pressure (bar) |

Filtration Area (cm²) |

Weight (kg) |

|---|---|---|---|---|---|---|

| YS-1 | 3/4" | 80 / 120 | 5 | 8 | 160 | 0.30 |

| YS-2 | 3/4" | 120 | 5 | 8 | 190 | 0.25 |

| YS-3 | 1" | 80 / 120 | 6 | 8 | 160 | 0.30 |

| YS-4 | 1" | 120 | 6 | 8 | 190 | 0.25 |

| YS-5 | 1-1/4" | 80 / 120 | 10 | 8 | 265 | 0.71 |

| YS-6 | 1-1/2" | 80 / 120 | 14 | 8 | 265 | 0.72 |

| YS-7 | 2" | 80 / 120 | 25 | 8 | 485 | 0.98 |

| YS-8 | 2-1/2" | 120 | 30 | 8 | 565 | 2.03 |

| YS-9 | 3" | 120 | 35 | 8 | 565 | 2.10 |

The T-type screen filter mainly consists of a filter element, a housing, and a top cover. Its inlet and outlet are usually located on the same side, forming a 'T' shape. This design is suitable for use in limited spaces.

| Model | H (mm) |

X (mm) |

D (mm) |

|---|---|---|---|

| TS-1 | 280 | 205 | 139 |

| TS-2 | 280 | 205 | 139 |

| TS-3 | 280 | 205 | 139 |

| TS-4 | 620 | 320 | 220 |

| TS-5 | 740 | 320 | 220 |

| TS-6 | 630 | 320 | 220 |

| TS-7 | 750 | 320 | 220 |

| TS-8 | 630 | 340 | 220 |

| TS-9 | 750 | 340 | 220 |

| Model | Connection Pipe Diameter BSP/NPT |

Filter Rating (Mesh) |

Maximum Flow Rate (m3/h) |

Maximum Pressure (bar) |

Filtration Area (cm²) |

Weight (kg) |

|---|---|---|---|---|---|---|

| TS-1 | 1-1/4" | 80 / 120 | 10 | 8 | 265 | 0.81 |

| TS-2 | 1-1/2" | 80 / 120 | 14 | 8 | 265 | 0.83 |

| TS-3 | 2" | 80 / 120 | 20 | 8 | 265 | 0.85 |

| TS-4 | 2" | 40 / 80 / 120 / 150 / 200 / 300 | 30 | 10 | 1200 | 4.8 |

| TS-5 | 2" | 40 / 80 / 120 / 150 / 200 / 300 | 30 | 10 | 1700 | 5.3 |

| TS-6 | 2-1/2" | 40 / 80 / 120 / 150 / 200 / 300 | 40 | 10 | 1200 | 4.9 |

| TS-7 | 2-1/2" | 40 / 80 / 120 / 150 / 200 / 300 | 40 | 10 | 1700 | 5.5 |

| TS-8 | 3" | 40 / 80 / 120 / 150 / 200 / 300 | 50 | 10 | 1200 | 5.1 |

| TS-9 | 3" | 40 / 80 / 120 / 150 / 200 / 300 | 50 | 10 | 1700 | 5.8 |

The main structure of the H-type screen filter is H-shaped, primarily composed of 2 stainless steel filter elements and a plastic housing. Its inlet and outlet are usually located on both sides, forming an 'H' shape. This design facilitates the observation and cleaning of the filter.

| Model | H (mm) |

W (mm) |

D (mm) |

|---|---|---|---|

| HS-1 | 940 | 335 | 220 |

| HS-2 | 1200 | 335 | 220 |

| HS-3 | 960 | 340 | 220 |

| HS-4 | 1220 | 340 | 220 |

| Model | Connection Pipe Diameter (BSP/NPT/GRV) |

Filter Rating (Mesh) |

Maximum Flow Rate (m3/h) |

Maximum Pressure (bar) |

Filtration Area (cm²) |

Weight (kg) |

|---|---|---|---|---|---|---|

| HS-1 | 3 " | 80 / 120 | 50 | 10 | 1630 | 7.8 |

| HS-2 | 3 " | 80 / 120 | 60 | 10 | 2174 | 9.2 |

| HS-3 | 4 " | 80 / 120 | 70 | 10 | 1630 | 8.2 |

| HS-4 | 4 " | 80 / 120 | 100 | 10 | 2174 | 9.6 |

The hand-cranked screen filter is a semi-automatic cleaning filter. It uses a hand-cranking device to brush away dirt, impurities, and other particles from the filter screen with an internal brush, and then discharges them through a drain valve, eliminating the hassle of frequent disassembly. The main feature of this filter is that the cleaning process can be conducted online without stopping the filtration process, making it suitable for various liquid filtration applications.

| Model | H1 (mm) |

H2 (mm) |

W (mm) |

X1 (mm) |

X2 (mm) |

D (mm) |

|---|---|---|---|---|---|---|

| SS-1 | 960 | 905 | 345 | 335 | 280 | 220 |

| SS-2 | 1085 | 1030 | 360 | 355 | 300 | 220 |

| SS-3 | 975 | 920 | 345 | 335 | 280 | 220 |

| SS-4 | 1100 | 1045 | 360 | 355 | 300 | 220 |

| Model | Connection Pipe Diameter (BSP/NPT/GRV) |

Filter Rating (Mesh) |

Maximum Flow Rate (m3/h) |

Maximum Pressure (bar) |

Filtration Area (cm²) |

Weight (kg) |

|---|---|---|---|---|---|---|

| SS-1 | 2" | 120 | 30 | 10 | 890 | 8.3 |

| SS-2 | 2" | 120 | 30 | 10 | 1190 | 10.1 |

| SS-3 | 3" | 120 | 50 | 10 | 890 | 8.5 |

| SS-4 | 3" | 120 | 50 | 10 | 1190 | 10.45 |