Search

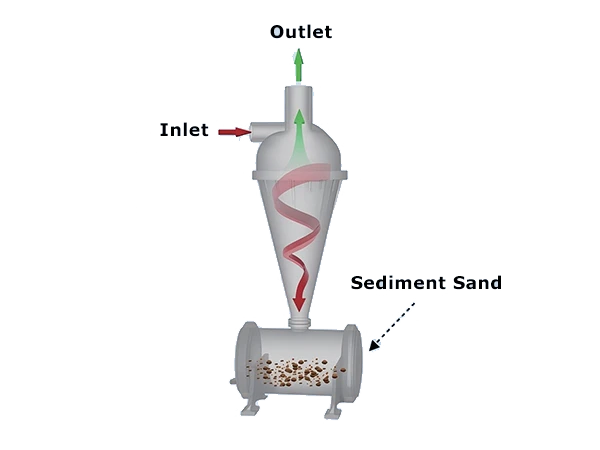

The centrifugal filter uses the principle of gravitational centrifugation to separate substances with different specific gravities, and it is particularly effective in filtering large sediment particles.

The centrifugal filter is made entirely of PA material, corrosion resistant and acid and alkali resistant. This greatly extends its service life and overcome the problem of rust and perforation in steel materials under sediment impact. The design of the bottom sand storage tank allows for easy maintenance and cleaning of filter impurities, and it is commonly used as a primary filtration device in irrigation systems.

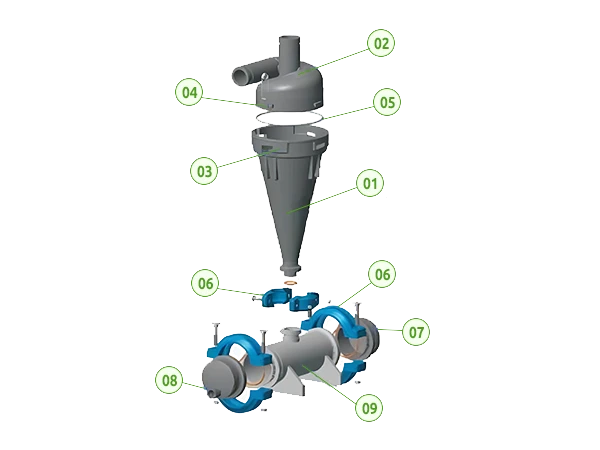

The main structure of a centrifugal filter consists of two parts: a centrifugal filter body and a sand storage tank. The body adopts a conical structure. It effectively addresses corrosion issues, enhances the machine's wear resistance, and alters the internal cyclone to effectively separate particles from the water. The design of the sand storage tank makes cleaning and maintenance more convenient.

The connection between the centrifugal filter body and the sand storage tank includes fixed locks, O-ring, reinforced clamps, etc.

Impurity-laden wastewater enters the centrifugal filter, where the uniquely designed flow path creates a centrifugal effect. Heavier gravel or debris gradually settles into the sand storage tank at the bottom under the influence of centrifugal force. Clean water flows upward and exits through the outlet, and the debris in the sand storage tank can be cleaned as needed.

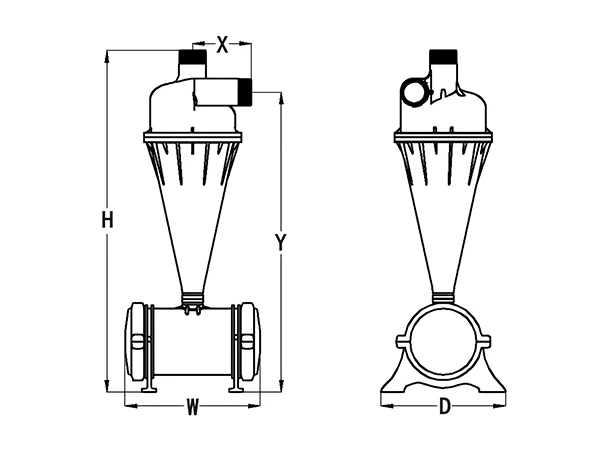

| Model | H (mm) |

W (mm) |

D (mm) |

X (mm) |

Y (mm) |

|---|---|---|---|---|---|

| LX-1 | 1100 | 490 | 430 | 180 | 963 |

| LX-2 | 1220 | 490 | 430 | 205 | 1070 |

| LX-3 | 1440 | 520 | 524 | 250 | 1260 |

| Model | Connection Pipe Diameter (BSP/FLANGE) |

Sand Capacity (L) |

Maximum Flow Rate (m3/h) |

Maximum Pressure (bar) |

Weight (kg) |

|---|---|---|---|---|---|

| LX-1 | 2" | 16 | 30 | 8 | 13 |

| LX-2 | 3" | 16 | 50 | 8 | 17.5 |

| LX-3 | 4" | 27 | 100 | 8 | 28 |